Fire Suppression is an Important Concern for the Safety of Employees and Business Continuity

Workplace safety is much more than not having to fill-up a Work Injury Claim Form. Safety measures account for evading every possible foreseeable danger so as to avoid the cascading aftermath of a potential accident. Since an ounce of neglect can cost many lives and irrecoverable damage, it's in the best interest of every employee to stay abreast of all safety measures at all times.

Companies take utmost care in complying with safety regulations instead of risking brand reputation and other implications that follow mishaps. When all the safety programs are in place, it's the employee who must follow and execute these safety steps. These essential safety tips for employees are sure to brush up your workplace safety awareness.

Declutter Workspace

The first and foremost safety tip is to keep your workstation clutter-free. Clutter will not only hinder your ability to work efficiently but it also poses a serious threat to your safety. Unable to perform a swift action at the spur of a moment due to an unorganized workstation can prove life threatening not only for you but also for others around you.

Ergonomics is not just choosing the right type of office furniture, it is also about organizing your workplace to suit your body & mind. Ergonomics is a science that uses a person's abilities & limitations to improve his interaction with things around him which considerably reduces the risk of injury.

Emergency Exit Ways

One of the safety training modules covered at your workplace would be the fire drill, to get you accustomed in finding your way towards emergency exits. This free safety training is for you to know that the pathway to these emergency exits must be clear of any obstruction. So do not ignore a stationary shelf blocking an emergency exit doorway.

Hazardous Zones

Familiarize yourself with the hazard zones of your workplace and take prompt action if you find something amiss in such high-risk zones. For example, damaged hazard signage is something that needs immediate replacement.

Combustible Dust

Apparently, dust can catch fire and cause an explosion too. It is important to identify areas that can accumulate dust and clean those areas regularly using industrial grade vacuum cleaners

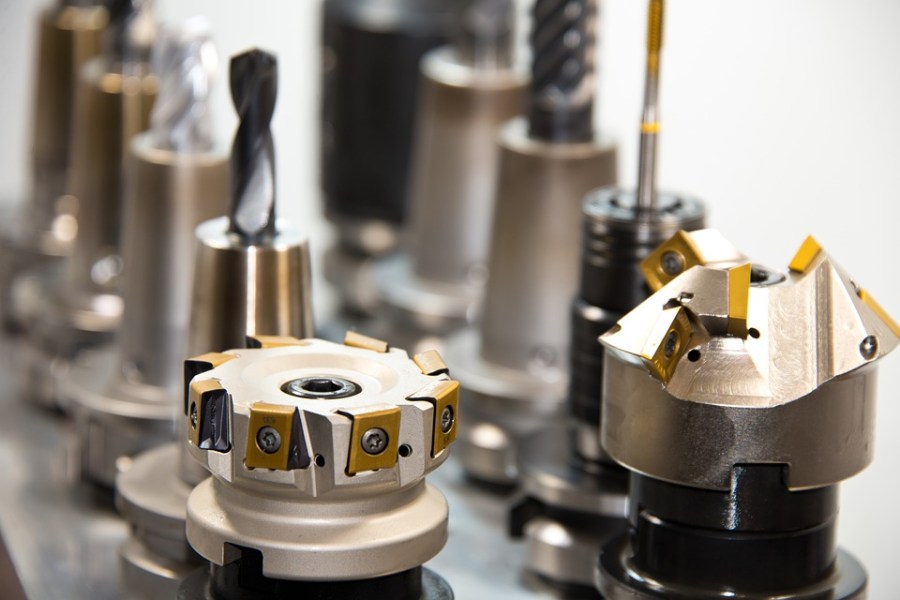

Machinery Manual

Keep the machinery manual handy not only for yourself but also for anyone else who may be using the same machine in another shift. This reduces injury due to improper use or lack of expert knowledge in using a machine.

Daily Toolbox Safety Talks

Toolbox safety talks are everyday prep talks that offer vital safety precautions and tips applicable to that day. It is recommended every employee attends these sessions to be able to take well-informed safety decisions throughout the day.

Tools & Machinery Service

Along with routine servicing, perform a visual inspection of your tools & machinery before using them. Something as simple as debris from your previous task can cause your equipment to malfunction & cause injury to the operator.

Protective Gear

Just like safety barriers are important for machines to be operated safely, protective gears protect employees from exposure to harmful substances. Protective gear includes but not limited to helmets, protective clothing, safety goggles, gloves etc.

Cross-Contamination Hazard

Cross-contamination proves to be a serious threat mainly in the food processing industry & the chemical industries. Being aware of the seriousness of cross-contamination and measures to avoid is one sure way to eliminate the risk.

Hospital Safety Plan

No doubt being prepared can save lives but in the unfortunate event of a medical emergency at the workplace, employees are required to act in an organized manner to ensure the injured is shifted to a hospital without any delay. Get yourself accustomed to the hospital safety plan of your floor to be prepared for medical emergencies.

Warehouse Safety

Employees need to be well-versed in safety fall prevention and ladder safety training to manage warehouses successfully. Since there is a whole lot of lifting and transportation involved in warehouse management, it is essential to have skill sets needed to prevent objects from falling.

Demarcated Unsafe Areas

Depending on the progress in work, the demarcated unsafe areas change with time in the certain workplace, especially in the construction & mining industries. Pay attention to safety guidelines for the day as what was safe the previous day may not be safe the following day.

Utilize Mechanical Aids

Never take shortcuts to avoid a few extra tasks you may have to do. Utilize mechanical aids when possible instead of doing the task yourself and reduce the chances of injury. For example, fetch a forklift to carry a heavy carton instead of maneuvering it around on your own.

Adequate Break Intervals

Last but not least, getting enough rest and recreation ensures you are alert at the task you are doing. Get sufficient rest & take adequate breaks to return to your task fresh and energetic to reduce the risk of injury.

etheridgepasto1975.blogspot.com

Source: https://www.questionsanswered.net/article/15-workplace-safety-tips-every-employee-should-know?utm_content=params%3Ao%3D740012%26ad%3DdirN%26qo%3DserpIndex&ueid=5e9325df-7e28-4f41-a16d-7bcc3761771a